At first sight, nuts or candy do not have much in common with French fries or shrimp. At second glance, the small portion packs for confectionery and the larger ones for frozen food do share a similar trait: they all come in vertically filled and sealed tubular bags. Producers around the world rely on different packaging solutions for different products, which often involves costly investments. Packaging their products with the same efficiency but on a reduced footprint could make production a lot easier – and is now within arm’s reach.

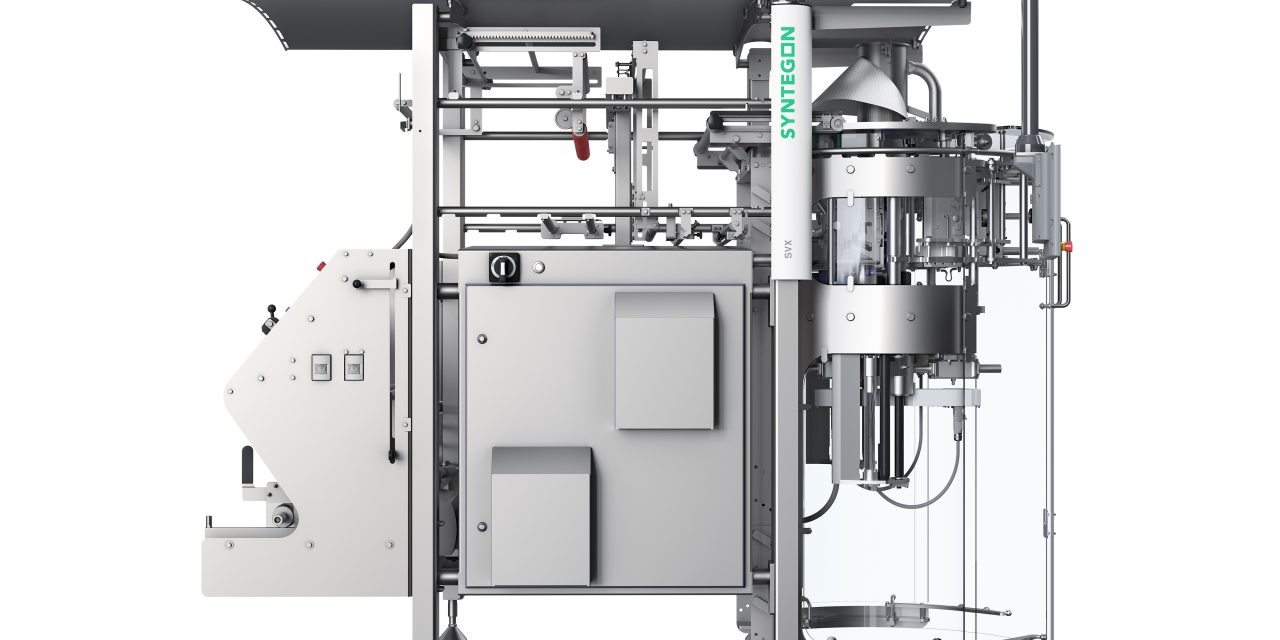

“We developed the SVX series with flexibility, ease of use, and transparency in mind,” says Martin Boutkan, product manager at Syntegon. This gives food producers across industries a leg up on competition: whether they fill products in small bags (with high output) or large bags (with lower output), the SVX series allows them to do so with just one machine. “Our series has one common base – the SVX Agile – that can always be upgraded to any bag style in the future”, Boutkan adds.

A future-proof approach

The SVX Agile lends itself to the high-output production of all bag styles, achieving a filling and sealing capacity of up to 300 bags per minute on a single film lane. Besides the SVX Agile Syntegon offers several options for end users who focus on smaller bags and want to benefit from a further floorspace reduction.

The SVX Duplex is a perfect example for this approach: the solution processes small packaging variants like pillow, gusseted and block-bottom bags with a maximum width of 145 mm, a type most seen in the confectionery industry. Other than the SVX Agile, it combines two lanes in the same 1,220 mm wide frame.

Albeit all SVX models are supplied as stand-alone solutions, they seamlessly fit into any new or existing packaging lines. The SVX series generally stands out in terms of flexible configuration, e. g. the machines can be mirrored to optimally meet user requirements. This includes set-ups with handling and cartoning equipment, such as Syntegon’s robotic pick-and-place system RPP and the Kliklok ACE carton erector. Moreover, the front height can be adapted to the product feed and the bag discharge. What makes the new series unique is the good accessibility of the machine’s back: all components remain at the ideal working height.

At customers’ service

Regardless of the line configuration, producers want to know how their equipment performs and where to optimize given processes. The SVX supports them with the integrated Synexio software: the cloud-based tool allows manufacturers to acquire, evaluate, and visualize machine and production information at all times. This data enables them to analyse, interpret, and predict key production processes.

Together with dedicated Service Agreements, Synexio helps producers ensure efficient start-up and smooth production. Seven Service Agreement levels comprise Syntegon services for all maintenance needs at a fixed price, from reducing production risks to gaining predictability over service costs and simplifying complex processes. “Now more than ever, unplanned downtime is a thing of the past, which results in considerable efficiency gains across food industries,” Martin Boutkan says.

Martin Boutkan

Product manager

E-Mail: martin.boutkan@syntegon.com

Phone: +31 495 574-225